The new

Busch and Muller Luxos dynamo headlights are setting a new standard for high-powered LED lighting, both in brightness and distribution of light. The Luxos U takes it one step further with a remote switch and USB charger.

All of the Luxos lights are able to be paired with a dyno powered tail light. The catch is that the tail light cannot be grounded to the frame or fender through the mounting screw. The will cause a fault circuit that detects a problem in the tail light. There will be problems with the functionality of the light and possible damage to the circuitry. This is a is a challenge because most of the popular fender mounted tail lights currently available offer the option of grounding through a wire or the mounting screw. My current favorite for both function and looks has been the

B&M Seculite plus.

I had already gotten my sample Luxos wired up and going when I became aware of the issue with a grounded tail light. At first I was a little bummed, then the challenge was set, and I decided to figure out how hard this was going to be to fix. It turned out to be fairly simple, and I have outlined the steps here for you.

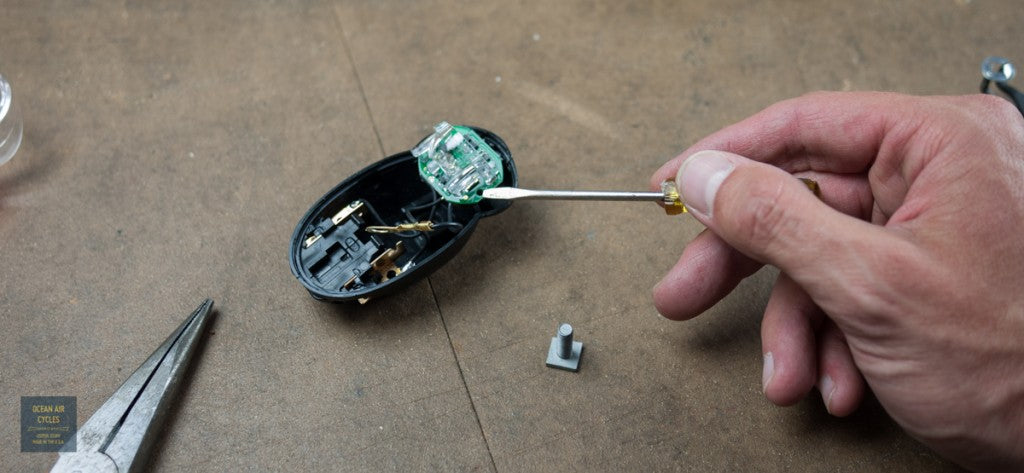

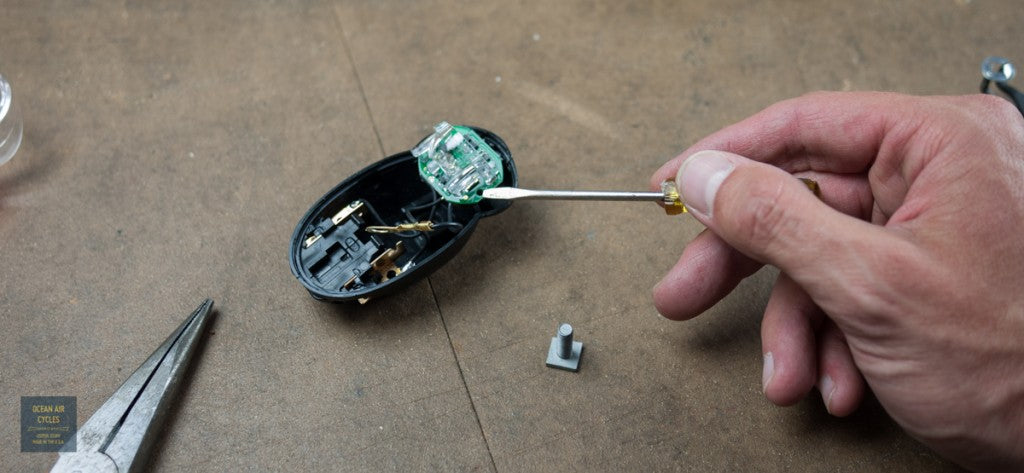

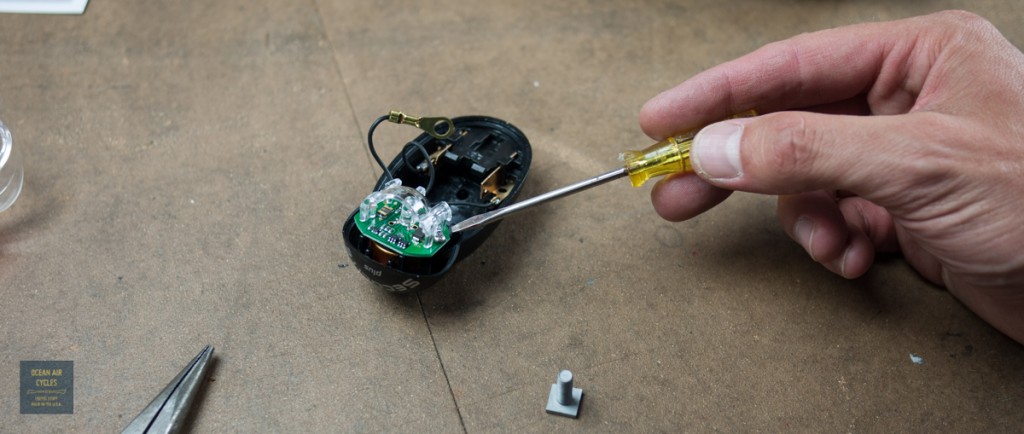

You will need a few basic tools: small flat head skew driver and small wire cutters will get you there, cir-clip pliers and a small Phillips head screw driver help make things a little easier.

The first thing I did was remove the nuts and washer from the mounting screw. The first is the standard hex mounting nut. Then there is the round washer style nut that holds the bolt to the light body

You can get this one off by carefully pushing it around counter-clockwise with the tip of your flat head screwdriver, but the cir-clip pliers made it a little easier.

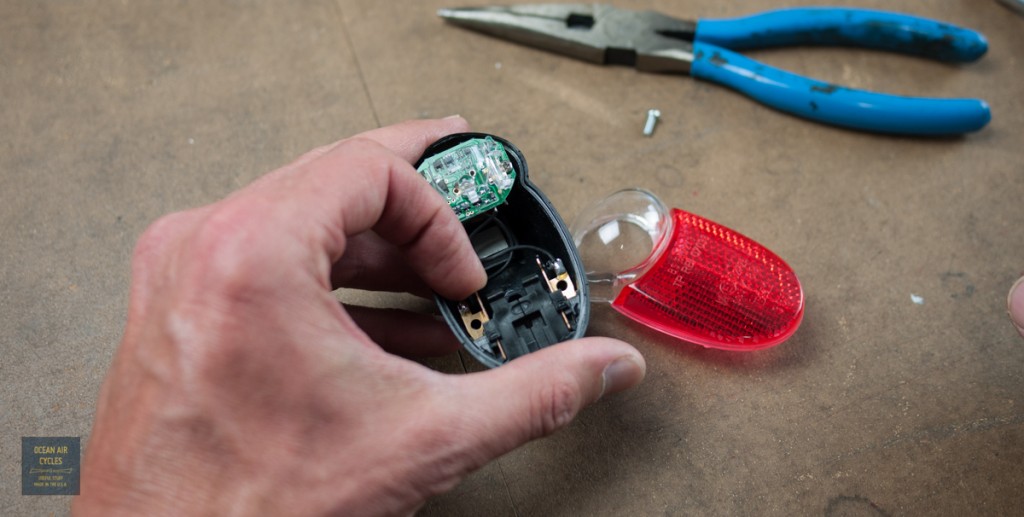

Once done you will be opening the light housing. Carefully work your way around the edges, starting from the bottom. The two halves of the housing are a press/snap fit together and can come apart safely as long as you are careful. I inserted the tip of the screwdriver into the thin gap between housings and lightly twisted to get it going.

As you approach the top you need to be extra careful. This is where there is a small tab that indexes the two halves together. At this point I stopped using the tool and gently separated the two halves with my hands

Once opened, you can easily see the above mentioned plastic tab.

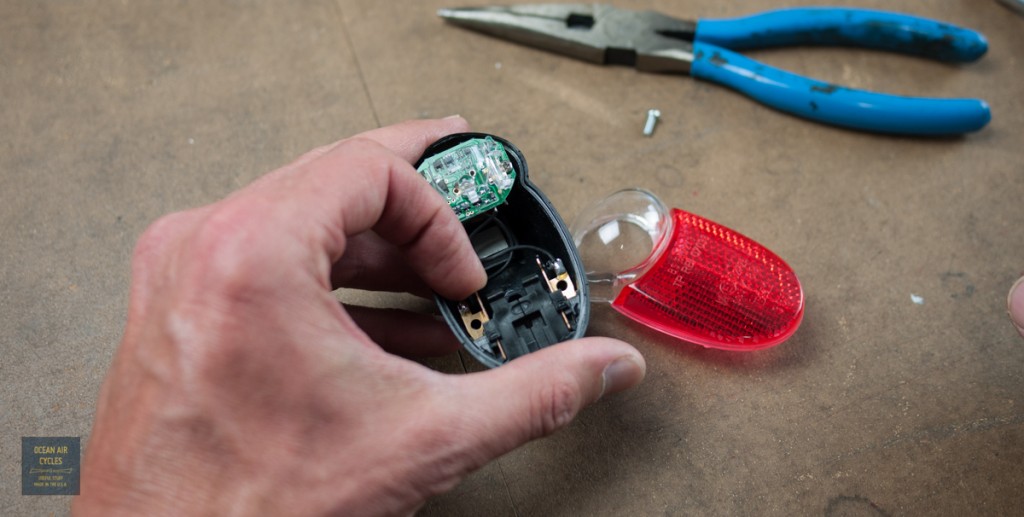

Moving on to the grounding of the light. The Seculite plus has two possible grounding paths. For most common installations involving a B&M headlight you will be wiring the tail light tot he front with a paired or co-axial conductor. The other grounding path is through the mounting screw. This is only used in cases where the frame of the bike and associated hardware are used as the grounding path. looking at the circuit board you can see both of the internal grounding wire options on the left side. The single wire on the left is for the positive lead.

The grounding wire to the frame mount needs to come out. It is connected to the mounting bolt with a ring connector. I was able to get the bolt out of the housing with the LED circuit board in place. If this is too tight for your comfort, you can remove the two Phillips head screws securing the board to the housing and you will then have plenty of room to work.

With the board out, you will want to snip the wire with the ring connector as close as you can to the board.

In theory you could leave the connector inside and isolate it, wrap it in electrical tape or shrink wrap, so that the process could be reversed. For this light I am pretty certain that it will never be wired with a frame ground path, so I snipped. While I had things appart I wired the Seculite into the Luxos U and confirmed that everything was as hoped.

The re-assembly is a pretty straight forward reversal of the above steps. Double check that the remaining wire connection points are fully seated in the housing.

Insert the mounting bolt and fasten in place with the thin nut.

Carefully align the two housing halves and squeeze together, they should snap into place and the light is ready for wiring and mounting to the bicycle as usual

For the home mechanic that is comfortable with electrical work this is not too bad of a project to take on. If you feel that this is above your skill level, and want a Luxos Seculite combo from us, I am more than happy to perform this procedure for free.

Rambler No.2 (Red) was going to be a cornerstone in the three bike heard that I am bringing to the SF expo in just a few days. At 57cm it is square in the middle if medium and most likely to be getting test rides, that is until the fork was blasted instead of chemical stripped, and it is not really clear how much steel is still there. After an assessment it was pretty clear that the fork is never going to be supporting a rider again, but it will hold up the front end of the bike for the expo, that is better than no bike and I decided to make lemonade with what I had.

The bottom of the right fork leg is pretty much gone just above the fork leg. I thought about some ways to stabilize it, headed up the street to FCD surfboards, and the guys let me have some resin. A tape mold, injection of epoxy through the vent hole and a few hours later I a confident that it will hold up to transport and display.

There is not enough left of the dropouts to mount a rack or fender, but I was able to make a Mark's rack work to hold up the light. That is when I went full in, and wired up the whole bike front and rear. This bike is the first one of the batch to get the full dynamo lighting system. That is front and rear lighting powered by the rotation of the front hub.

The chain ring bracket is perfect. The wire from the hub to the headlight runs through the guides on the right fork leg.

The curly q wire allows the lighting wire to be installed or removed with the connectors intact on the wire ends. I first saw this either on Alex Wetmore's blog or on Flicker someplace. It works better than solid loops that will not pass the connectors in the event that you need to strip the lights with intentions of putting them back on.

In an ideal world the wires would be tucked under the fender for the run from the crown to the headlight and the returning tail light wire. This being what it is, they are tied off to the rack. The tail light wire enters into the frame through the port at the top of the down tube.

It passes along, protected from snagging, inside the down tube, around the bottom bracket and up the seat tube just a bit to the exit port.

There is a short exposed run along the left chain stay before it tucks into the rear fender. To protect the wire from being cut by the sharp fender edge I used a commonly available rubber stress relief grommet.

the wire then runs along the inside edge of the fender. The Berthoud fenders are quite nice for this as the edge is rolled, but not crimped completely shut as it is on some other brands of metal fenders.

Once fully tucked in, you can crimp the channel shut just a bit, or use a few short beads of silicone to hold it in place. The wire exits the rear of the fender through, another stress relief grommet, and then connects up to the tail light.

A quick spin of the front wheel to confirm that everything is still working and it is almost time to clean up. I decided to secure the short run of wire between the seat tube ans the fender with a piece od red reflective tape that was a close enough color match.

While not everything I had dreamed for a complete bike, I am still pretty happy with the results, and when the replacement fork gets here it should go together pretty quickly.

I took a time out in the shop this morning to make some new light brackets. The only thing better than caffeine in the morning is jumping out of bed and making an idea into reality with your hands, at least for me. The idea of chain ring light brackets is not new, a little google-fu will get you some results like this:

Working from this as a starting point, I went through my piles of old chain rings and decided that the diameter of chain rings in the mid to high 20's best matched the shape of the headlight. After a bit of cutting, filing, and polishing this is what I came up with:

I am pretty happy with the way they came out. Both lights will be mounting to a Nitto Mark's rack, in different ways, so I made two different length brackets.

Backing up a bit for those not familiar with these types of lighting systems, one is likely to ask why even make a bracket? Why not just mount it upside down? The lights are made with a fairly advanced optic that focuses the light in a rectangular beam with a cutoff that keeps the light on the road and out of the eyes of oncoming traffic. The optic housing interface is further designed to be most water-resistant in the upright orientation. This all works out fine for 90% of the intended audience who mount these lights to the fork crown of an average city bike. The challenge starts with the crown mount location when you use a front bag or basket. The lights beam is obstructed in the competition for real estate. So a bracket needs to be used to move the light under the rack and forward so that the light is not blocked by the front wheel or hanging out in a spot where it can be easily damaged. Surprisingly there is not much on the market to solve this problem.

I am waiting for some additional hardware to be delivered so I can keep this project moving. Later in the week I should have this much further along.

I had already gotten my sample Luxos wired up and going when I became aware of the issue with a grounded tail light. At first I was a little bummed, then the challenge was set, and I decided to figure out how hard this was going to be to fix. It turned out to be fairly simple, and I have outlined the steps here for you.

You will need a few basic tools: small flat head skew driver and small wire cutters will get you there, cir-clip pliers and a small Phillips head screw driver help make things a little easier.

I had already gotten my sample Luxos wired up and going when I became aware of the issue with a grounded tail light. At first I was a little bummed, then the challenge was set, and I decided to figure out how hard this was going to be to fix. It turned out to be fairly simple, and I have outlined the steps here for you.

You will need a few basic tools: small flat head skew driver and small wire cutters will get you there, cir-clip pliers and a small Phillips head screw driver help make things a little easier.

The first thing I did was remove the nuts and washer from the mounting screw. The first is the standard hex mounting nut. Then there is the round washer style nut that holds the bolt to the light body

The first thing I did was remove the nuts and washer from the mounting screw. The first is the standard hex mounting nut. Then there is the round washer style nut that holds the bolt to the light body

You can get this one off by carefully pushing it around counter-clockwise with the tip of your flat head screwdriver, but the cir-clip pliers made it a little easier.

You can get this one off by carefully pushing it around counter-clockwise with the tip of your flat head screwdriver, but the cir-clip pliers made it a little easier.

Once done you will be opening the light housing. Carefully work your way around the edges, starting from the bottom. The two halves of the housing are a press/snap fit together and can come apart safely as long as you are careful. I inserted the tip of the screwdriver into the thin gap between housings and lightly twisted to get it going.

Once done you will be opening the light housing. Carefully work your way around the edges, starting from the bottom. The two halves of the housing are a press/snap fit together and can come apart safely as long as you are careful. I inserted the tip of the screwdriver into the thin gap between housings and lightly twisted to get it going.

As you approach the top you need to be extra careful. This is where there is a small tab that indexes the two halves together. At this point I stopped using the tool and gently separated the two halves with my hands

As you approach the top you need to be extra careful. This is where there is a small tab that indexes the two halves together. At this point I stopped using the tool and gently separated the two halves with my hands

Once opened, you can easily see the above mentioned plastic tab.

Once opened, you can easily see the above mentioned plastic tab.

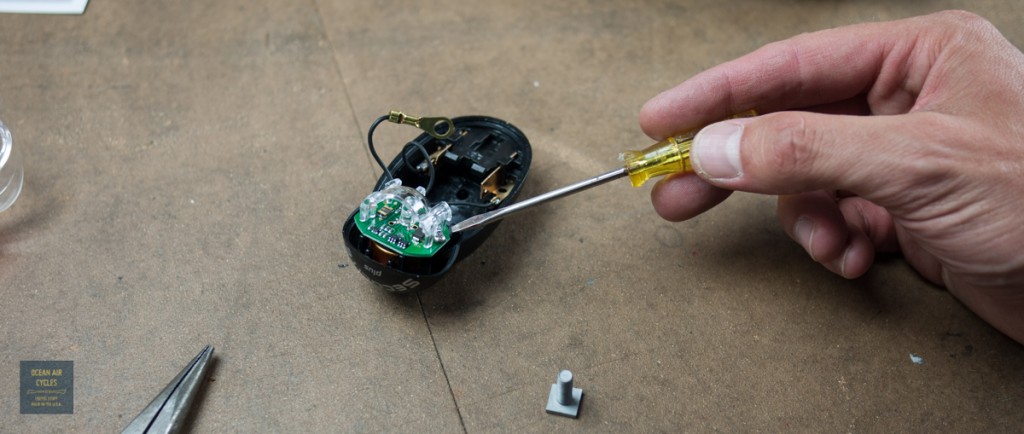

Moving on to the grounding of the light. The Seculite plus has two possible grounding paths. For most common installations involving a B&M headlight you will be wiring the tail light tot he front with a paired or co-axial conductor. The other grounding path is through the mounting screw. This is only used in cases where the frame of the bike and associated hardware are used as the grounding path. looking at the circuit board you can see both of the internal grounding wire options on the left side. The single wire on the left is for the positive lead.

Moving on to the grounding of the light. The Seculite plus has two possible grounding paths. For most common installations involving a B&M headlight you will be wiring the tail light tot he front with a paired or co-axial conductor. The other grounding path is through the mounting screw. This is only used in cases where the frame of the bike and associated hardware are used as the grounding path. looking at the circuit board you can see both of the internal grounding wire options on the left side. The single wire on the left is for the positive lead.

The grounding wire to the frame mount needs to come out. It is connected to the mounting bolt with a ring connector. I was able to get the bolt out of the housing with the LED circuit board in place. If this is too tight for your comfort, you can remove the two Phillips head screws securing the board to the housing and you will then have plenty of room to work.

The grounding wire to the frame mount needs to come out. It is connected to the mounting bolt with a ring connector. I was able to get the bolt out of the housing with the LED circuit board in place. If this is too tight for your comfort, you can remove the two Phillips head screws securing the board to the housing and you will then have plenty of room to work.

With the board out, you will want to snip the wire with the ring connector as close as you can to the board.

With the board out, you will want to snip the wire with the ring connector as close as you can to the board.

In theory you could leave the connector inside and isolate it, wrap it in electrical tape or shrink wrap, so that the process could be reversed. For this light I am pretty certain that it will never be wired with a frame ground path, so I snipped. While I had things appart I wired the Seculite into the Luxos U and confirmed that everything was as hoped.

In theory you could leave the connector inside and isolate it, wrap it in electrical tape or shrink wrap, so that the process could be reversed. For this light I am pretty certain that it will never be wired with a frame ground path, so I snipped. While I had things appart I wired the Seculite into the Luxos U and confirmed that everything was as hoped.

The re-assembly is a pretty straight forward reversal of the above steps. Double check that the remaining wire connection points are fully seated in the housing.

The re-assembly is a pretty straight forward reversal of the above steps. Double check that the remaining wire connection points are fully seated in the housing.

Insert the mounting bolt and fasten in place with the thin nut.

Insert the mounting bolt and fasten in place with the thin nut.

Carefully align the two housing halves and squeeze together, they should snap into place and the light is ready for wiring and mounting to the bicycle as usual

Carefully align the two housing halves and squeeze together, they should snap into place and the light is ready for wiring and mounting to the bicycle as usual

For the home mechanic that is comfortable with electrical work this is not too bad of a project to take on. If you feel that this is above your skill level, and want a Luxos Seculite combo from us, I am more than happy to perform this procedure for free.

For the home mechanic that is comfortable with electrical work this is not too bad of a project to take on. If you feel that this is above your skill level, and want a Luxos Seculite combo from us, I am more than happy to perform this procedure for free.