This morning while working trough my coffee and web reading I came across a picture that stirred a few emotions, and led me down a path of some further googling, landing at this video that is a few years old:

I am at a juncture with OAC where I either need to sell a truck full of bikes this week, find another round of funding or get a day job. As much as I would like the first option to happen, the later is the most likely scenario. (

note: A day job does not mean OAC is going away, just that I need to keep cash flowing to help support the household) That in turn has me thinking about the fact that I will be doing a "job" to meet and exceed somebody else's expectations. This is part of life, and I happen to be pretty good at it, IMO. While the model here at OAC is based on sourcing as much as possible here in the USA, then having fabrication and finish completed here, that is not the most profitable model most companies are using these days. I hold no illusions as the cost differences of have things made here as opposed to abroad. The labor cost difference is huge, there is a good reason the Rambler costs almost twice what a similar option does, and trust me, it is not a mountain of profits in my pocket. The video above makes Maxport look like a pretty good place to work, nicer than many US factories of the past or present. The thing is, that the word sustainable gets thrown out quite a bit, with an inference towards long term. But what does that mean? Not to poke Maxport in the eye, since I do not know them, but what keeps them or future employees from acting out much the way Giant did as an OEM bicycle builder? What will sustainable mean for their employees in a few years when a similar factory opens up in a different part of the world where the labor costs result in a more profitable product? Will the Vietnamese economists tell their "boomer" generation to suck it up and adapt to the new world why their adapted younger generations struggle to find jobs?

As the making of things has been leaving our shores and cheaper labor draws the work in, economists have warned that we in the US need to re-tool and come up to speed with the knowledge economy, and figure out how to sell services. I think there is a catch to that though. What do we as a country do with the millions of people, multiple living generations, who are by no fault of their own, predisposed to being content worker bees, makers of stuff on a production level? There is a great deal of joy and pride to be found in the making of stuff, even at a production level. There is still plenty of hope for our country IMO:

Quoddy Workshop - Lewiston, Maine from

Oliver Wilkins on

Vimeo.

What is the catch? Stuff made her costs more, because things here cost more for people to live. Thus the consume is still the one who has to be willing to change the game, make the choice of where and who they want making their stuff. Does made in the USA mean better? Not always, and there are plenty of people and factories around the world who can make some things better, and as we know for a lower price. I still think we need to keep the work at all levels in out own yard. It is a complex economic mess at the moment, but I do know that the factories all over our country are shutting down faster and faster. The river beds in our region are filling even faster with "campers" in search of the temperate climate and easily found foods. Something has to give. It is up to us to make the choices with our wallets that will bring on the change in our own playground. I have no problem with people in other countries, or the fact that they make things. I just like me, my neighbors and countrymen to have a fighting chance at long-term success. Made in the USA does matter, it makes a difference in how many people are shopping in the grocery store as opposed to standing out front with "will work for food" signs

The picture sparking this morning's rant from the FYIdesigndept blog?

I may have shot myself in the foot as I click on publish, or sparked the fire of change, time will tell. Now back to work, so there will be time for a ride at lunch.

Earlier this week I headed out with a couple of buddies on a two day tour on the central coast of California. The trip was originally conceived by two different friends who ended up having to pass on the trip, and that is a shame, as it was a fantastic ride. Mike, Jefe and I met up Monday Morning to take the Surfliner (Amtrak) up the coast to the small coastal station of Surf. Day one was the ride to Buelton, camp overnight, and then over the mountains and down the coast home. Pictures, as always will tell most of the story:

View of "The Ranch" from the train, this strech of open coast is all privately owned and off limits for most of us. I dream often of being able to ride and surf there. Beautiful open land, the way this stretch of coast has been for hundreds of years.

Surf Train Station, no Cell coverage, nothing but you, the beach and a road out. Not a place you are likely to end up by accident.

Out of the coastal fog, through Lompoc and heading down Santa Rosa rd. This is an incredible example of the hundreds of miles of country roads the California central coast has to offer.

Yes it was hot, and consensus was clear, it was time to stop and sample the local "grape juice"!

To help keep things light we ate in restaurants, Buelton is home to a few good ones, and we picked Firestone Brewery. Sorry no Pics, hunger was over riding the creative side of the brain. The Burger was fantastic, I could have had two, but logic prevailed. The Flying Flags campground was pretty nice. Although, next time we all agree that we would rather push a little further into the ride for the first stop.

The next morning started with a few miles to wake up and grab some breakfast in the next town of Solvang. The whole town is Dutch themed, one of those places you have to visit to really understand. Bellies full, we pushed off.

This was the start of the real climbing on Refugio Rd., 4 miles of sustained 10-14% grades. The legs were willing, the heat was climbing, and I will admit, that I opted to hike-a-bike through plenty of sections. I was carrying too much weight for this leg of the trip. I had looked at the map and elevations, but did not really appreciate it until I was all the way immersed. It was hard going up, I was focused on making the top, and the camera never came out for the next hour.

Over the top and well above the coastal fog. At the break between the fog and horizon you can just make out the top of the channel islands. The ride down was a blast, but Refugio Rd is in terrible condition, many potholes. I elected to keep my hand on the bars and not fool around with the camera.

Heading into Santa Barbara. As we worked our way South East along the coast, we were flirting with the edge of the fog bank the whole way. The summer temperatures were cool and crisp, but the regular tailwind never made an appearance.

The last view back up the coast before the final 10 mile push home.

The trip was perfect, the company, weather, terrain etc. This is sure to be a stepping stone for more local rides like this. The whole thing was comfortably pulled off in just over 36 hours. I could have brought less, we could have done a few things differently, but it all worked out. My legs are the only part that is not in a state of recovery this week. I am still processing my thoughts on the trip and will be sharing them over the coming weeks as I make some changes in my gear. The Rambler continues to exceed my expectations for this type of riding, and we are all looking forward to getting back out there.

Thanks Mike and Jefe for helping to make it all happen.

Summer Fog July 26 2012, 0 Comments

Sumner on the SoCal coast almost always means fog, at a minimum in the mornings. Some days it pulls back out to sea, some days it tries, but teases you.

Hopefully it pulls out by the afternoon, we could use the sun.

One way, over the mountains and down the coast with friends, one night in a tent, two days of riding. Now to sort out things like camera gear and camping equip., while keeping everything as light as possible.

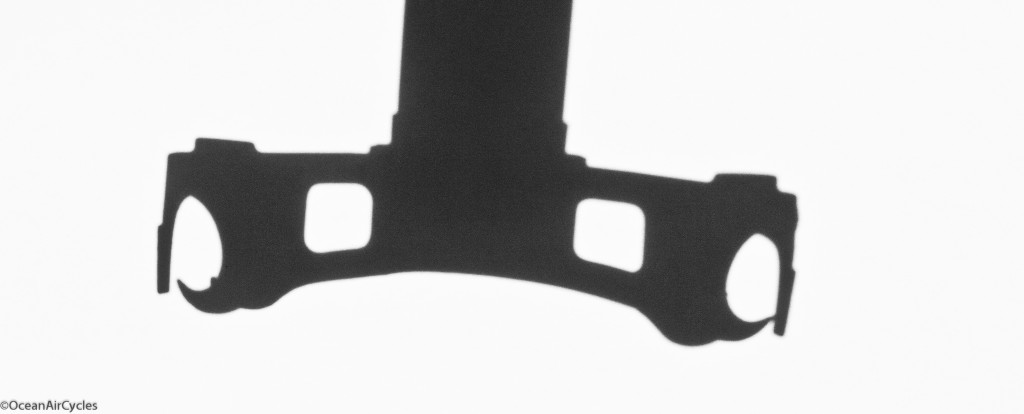

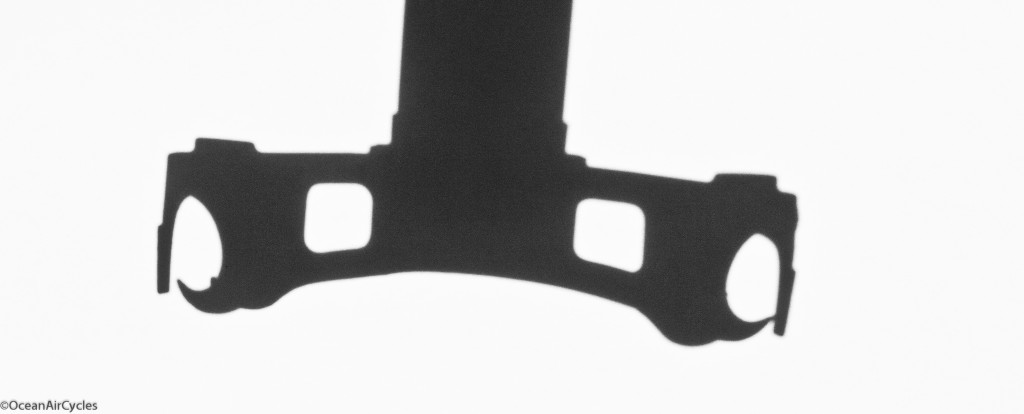

I have been working with Kirk Pacenti of bikelugs.com fame to get the Paris Brest fork crown made with M5 rack bosses built into the shoulder of the crown during casting. I Samples are here and I am very excited for these.

Until now if you were working on a Porteur / Randonneur style of bike you options were limited to bosses that were hand brazed into the top of the fork. Having the bosses as an integral part of the casting will shave man hours and result in a stronger more consistent product. These crowns will make this style of front rack mount more approachable for builders and designers.

There are a couple of strong benefits to having crown mounted rack bosses. Foremost is the added stiffness you will get from a rack with two well spaced upper mounting points as opposed to the more common single point in the center. Running a close second is having redundancy of upper mounting points, two is better than one. If a bolt were to come loose or a rack strut fail, the loaded rack is less likely to immediately drop into the rider's front wheel. I believe this mode of failure is more common than thought if the number CPSC recall notices on production front racks is any indicator.

I hope that by pushing this fork to market we will see an increase in the number of well designed front loading bikes and front racks on the market in the coming years. The crown specs are the same to the existing Paris Brest in every way other than the added rack bosses. Spacing between holes is 80mm. If we as designers and builders were to adopt this as a standard it will help with the proliferation of the niche. bringing a level of consistency across brands.

After talking with Kirk today, these crowns will be available through Bikelugs.com in 6-8 weeks.

Once the word got out locally that I am the "bike guy", I have started to get more and more general inquiries. In particular from people looking to commute, or get around town, carry stuff on their bikes etc. One of the most frequent questions I get is "what type of bike should I get?". I like this much more than the customer that comes in with a strong notion about a certain bike or set up. I usually respond with the question, "what do you want the bike to do"? Surprisingly this catches most people off guard. The thing is, while a bike like our Rambler can be a 80% or more car replacement, go fast as you want, carry the average load, etc. it is a bit more than the casual rider may want. Particularly if new or coming back to cycling after a long break. Luckily the bicycle market place is starting to shift a bit from the race and extreme categories, with more practical offerings. Many a bike snob would turn their nose up, but in reality these bikes are what will be helping to widen the pond for the transportational cyclist.

Today I had the chance to help a friend of a friend (see above for word getting out) with the assembly of an Electra Amsterdam. This bike is honestly a refreshing build in a world of race and fashion bikes.

Many of the details you would expect to see on fancier bikes are all there and well addressed. Out of the box, it comes with full coverage fenders, a full chaincase, wide comfortable tires. The seat and controls are comfortable and stylish. Front and rear brakes, 3 speeds. This bike is honestly all that the average commuter will need. Particularly in a small relatively flat town like ours. Just about anyone who can walk could use this bike to replace their car for all trips under 4 miles, and still get around in business attire without breaking a sweat

With a rack and some panniers, this could be the 80% car replacement for plenty of riders. I believe strongly that the world needs more bikes like this, particularly in the US. The tide is shifting, and I am happy to be part of the wave helping get riders on bikes like this.

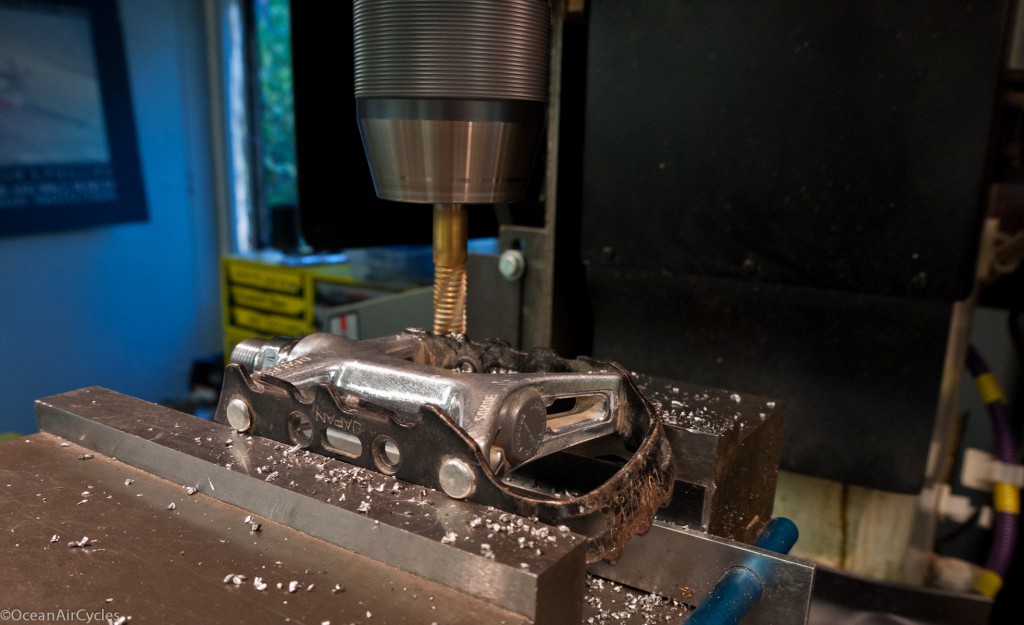

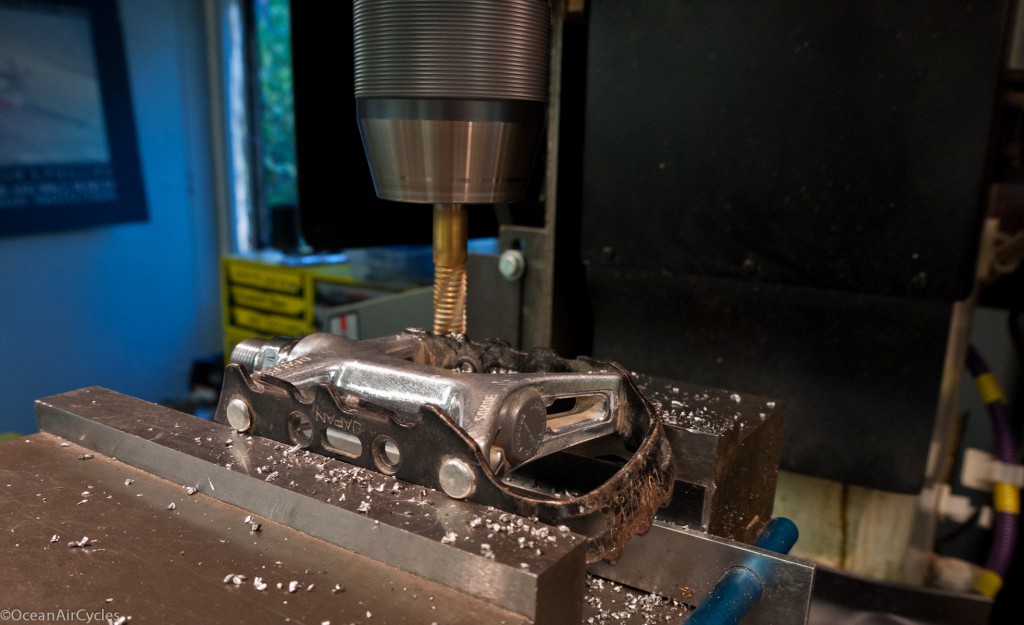

Over the holiday we spent some time with family on the central coast, a fringe benefit of which is access to an uncle's machine shop. The last few times up there, things were too busy to get any projects worked into the schedule, and this trip was the start of catching up.

I have a love affair going on with the no longer made Sakae Low Fat pedals. They have just about everything I thought I wanted in a pedal, wide, light-ish, easy to service, durable, a full cm wider than anything else on the market, etc. The down side is that they have not been made for 15 years or more. Needless to say I have a bit of a horde. Then came the Specialized touring pedal, just an idle curiosity at first. The Low Fat seemed so rough around the edges, even chewing holes in the bottoms of some of my shoes. The touring pedals, also no longer made, seemed so much closer to what I wanted in an every day, practical sort of road pedal. Much more refined, lacking traction spikes, my feet still never slipped, the finish was almost like jewelry, really nice. But they were lacking too, while wide, the end shape was awkward to use with clips, straps and my Flintstone feet. So close to perfect, missing the mark by a little as well.

I decided it was time to start working out what I really wanted the pedals to be and make it a reality. Using a beat up set of Low Fats as a starting point, it was off to the mill. They were a bit awkward to clamp in the vise, the mill was still a better starting point than a file. I knocked off all of the teeth, excepting the toe flips, and brought the edge of the cage a little closer to the pedal body.

There is still a bit of clean up, fitting of the toe cages, etc. to get these ready to roll, but I am excited to give them a go. Here you can see a pair before and after;

I was able to squeeze in one more project, and turn a couple of headset spacers for our tandem, another languishing project.

The project list is still long, I wish I had my own machine shop, more shop space in general, but am incredibly grateful to be able to visit and use my Uncle-in-law's shop - Thanks Marty

While photography used to be the main thrust of OAC, it has taken a bit of a back seat to getting the Ramblers and the rest of the product line in order and off to market. There is a tiny bit of irony in that while the blog went a bit dormant, I actually have ended up having a couple of my photographs requested for use in print. First up, the Summer issue of Momentum magazine, it should be on the stands or on its way to subscribers by now. I pulled out the ruler to confirm, but it is close to 20% of the page, not bad

The magazine just happened to be on top of the 99% art for the decals when I took the pic of a pic ;-)

I should also have a picture in the upcoming Environmental Initiatives publication for Patagonia. That one is very exciting. While the blog and my flickr accounts see a fair amount of traffic, it is extremely rewarding to have my work showing up in print. Particularly in places that will have a more diverse exposure, and an audience beyond the small world of bike geeks.

Things are heating up, lots and lots of projects, the blog has taken a back seat for a bit, and I am sorry for that. The next week or two should be pretty consistent, lots of pictures, a few bike build projects, and I may even find the time to get out and ride a bit.

Samples July 01 2012, 0 Comments

I took the Rambler out for a shakedown ride to the Farmers market. Although, it was not quite "fender" weather.

In the last couple of days I was able to get the VO Zeppelin fenders onto Rambler No.1. Overall I would say it went pretty well. The VO fenders require a bit of re-shaping to get the fender line just right, no big deal though. Mount up to the rear connection points went as planned, but there will be some fine tuning on bridge locations for the production run. Likewise with the front, we knew the crown was a couple of mm low compared to the production spec.

I ended up using the top mounted angle bracket for the front fender. The daruma bolt was just grazing the top of the tire. Production frames will have the crown about 5mm higher, and all should be good in the fender world. Things fit with the 42mm Nomads and 52mm fenders, but it is tight. This is not really the fault of the bike as there is still a few mm of space at the frame and brake contact points. The trick is finding a 58mm fender for a 700c tire. Fit would be superb with 38mm tires or a slightly wider fender. That sounds like another project for another day.

I have had a few questions about racks. So far I have fit both the Bruce Gordon Lowrider and the Nitto Mark's Rack with no modification to the racks. Production frames will have the mid fork braze on located for an easy installation of both of these off the shelf racks.

The Mark's rack is currently mounted to the crown with the center bracket. There is plenty of room for the Paul brakes full range of motion. With a little bit of strut bending the rack can be attached at four points to the bosses brazed into the crown.

In the long run I intend to offer a custom three-piece rack designed to incorporate the strong points of both of these racks into a singular modular system.